Hot Wire Plastic Bender

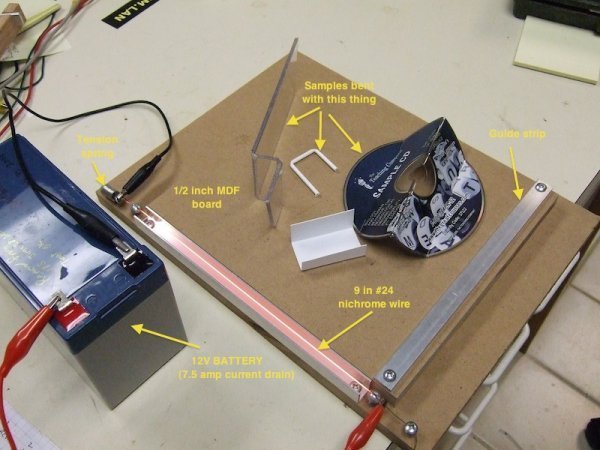

This is a simple hot wire plastic bending jig I made. It can be used to bend thermoforming plastics up to about 1/8 inch thick. I€™ve bent polystyrene and polycarbonate and PVC.

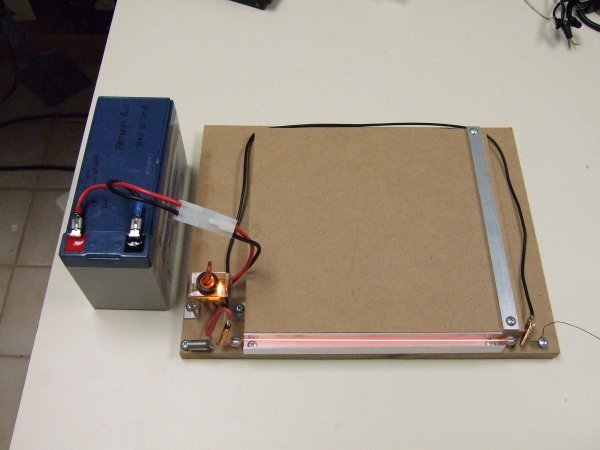

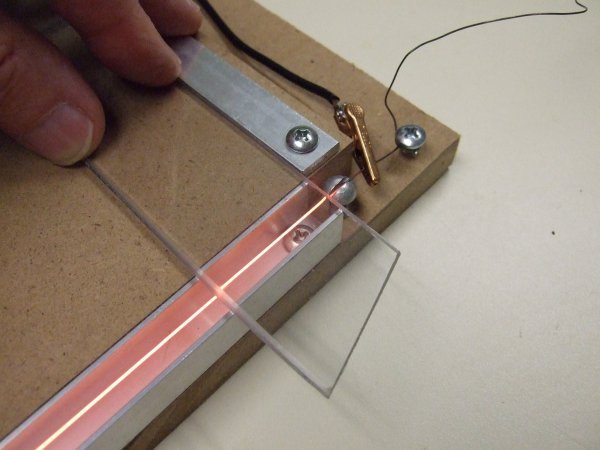

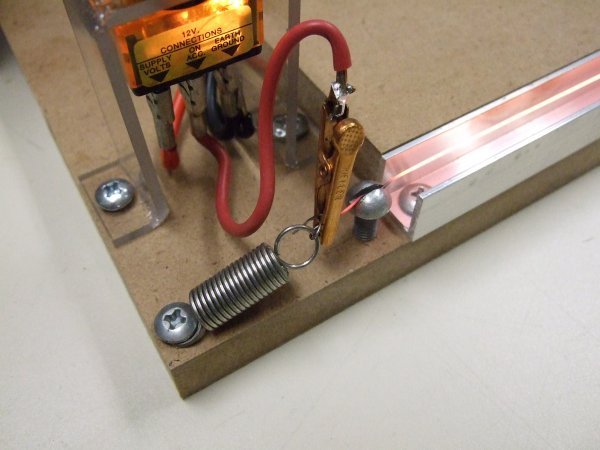

The base is 1/2 inch multi-density fiber board (MDF board) The heater wire is suspended in a piece of 1/2 inch aluminum channel supported by two slotted 10-32 screws. A small spring on one end keeps the wire from sagging when it gets hot. Note the hot wire does not touch the plastic. It is located 0.080 inch below the work. I installed a 1/2 x 1/16 inch aluminum guide strip perpendicular to the wire to help align the work.

Here it is after I added a power switch, battery connector and permanent wiring. I still use alligator clips to connect to the hot wire. The battery is a 12 volt, 7 Ah SLA unit. Some people like to use a variable AC power supply such as a variac. This allows variable temperature.

There is 9.25 inches between the two clips. This works out to 1.25 ohms.

Nichrome wire also may be salvaged from toasters and electric heaters.

How to bend plastic with this thing

Position the work with the bend line over the hot wire and turn on the power.

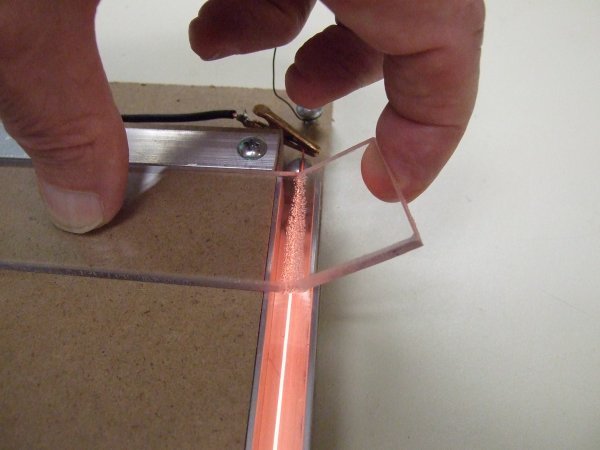

Put tension on the work until you notice it soften and start to bend. Here you see bubbles forming in Polycarbinate. Polystyrene does not have this problem.

Update: I have recently found out that the bubbles in polycarbinate/Lexan can be eliminated by heating it in a oven at about 230 degrees for about 30 minutes before you bend it. This removes the moisture that causes the bubbles.

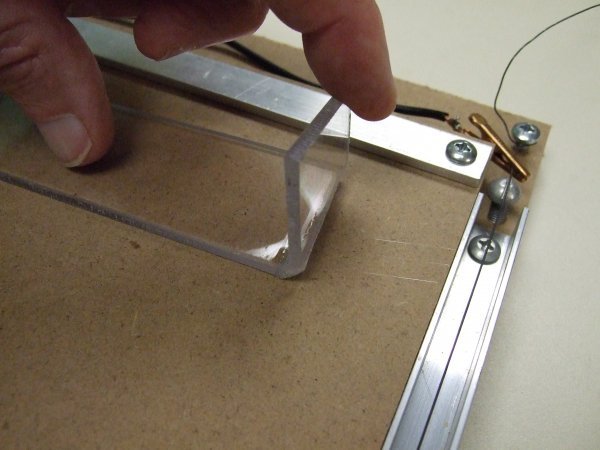

Quickly move the work off the hot wire and bend it to the desired angle and hold it until it cools.

Hit Counter 114464

Previous page: 14.4 Volt DrillMaster Modification

Next page: Ooma Telo + Apple Airport Extreme