Pushy Grabber

Updated August 8, 2019

June 2017

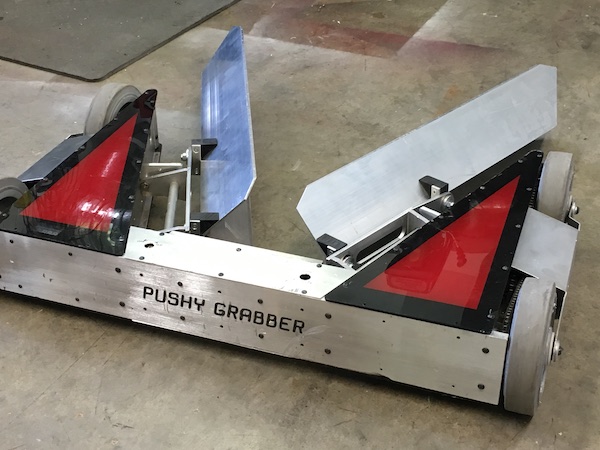

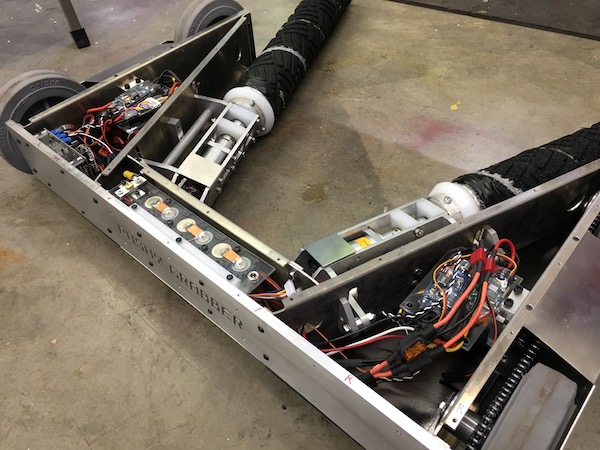

Meet Pushy Grabber, my new 30# bot designed for open stage sumo competition at Robot Battles events. The weapon system is basically a pair of counter rotating cylinders that grab and lift the opponent by the sides. This method proved very successful in my Huggy Bear mini-sumo bot. The rollers are controlled with my left joystick and can go forward, reverse and left or right. They are on hinges so they work when the bot is inverted. The bots "brain" uses an accelerometer to sense when the bot has flipped over so it can automatically reverse the controls.

Below is the frame. The rear panel is 3/8 inch 6061-T6 aluminum. The other pieces are .090" 7075 aluminum. You are probably wondering how I bent 7075 ninety degrees without cracking it. Well, there were a few steps including getting a new furnace to handle the long pieces. This is the process:

I used 7075-0 stock which is annealed and therefor bendable. During the CNC cutting operation the bend lines were scored with a 60 degree V cutter .032" deep. That made it easy to accurately make the bends. Unfortunately 7075-0 is very soft and will clog end mills. I had to use lots of mist coolant and take many shallow passes to avoid cutter clog.

Next I had to harden the 7075. After the bends were done I placed the pieces in the furnace at 925 degrees F for 20 minutes then plunged in cold water immediately. After the abrupt cooling they were placed in a toaster oven at 250 degrees for 24 hours. This is like Viagra for aluminum. What was soft and supple becomes stiff and springy.

Added drive motors, wheels, chain drive and weapons. I used #25 roller chain. Drive sprocket has 16 teeth, the wheel sprocket has 30 teeth for a ratio of 1.875:1 . The gearbox is 26:1 from Banebots . This spins the 6" wheels at almost 400 rpm max. Full speed is a little under 10 feet/second.

Banana for scale.

Chain guards installed. Made from .063 6061-T6 aluminum cut with a band saw. Paper templates were glued on to mark cuts and holes.

This is one of the brushless out-runner drive motors bolted to a Banebots 26:1 gearbox. Tiny but powerful.

Another view.

Here is the weapon drive unit. It's a 1000KV brushless out-runner geared down 81:1 to drive the roller at about 200 RPM max. The large homemade UHMW bearings handle the side load so the gearbox doesn't have to. They are a little soft so I may need to replace them with Delrin .

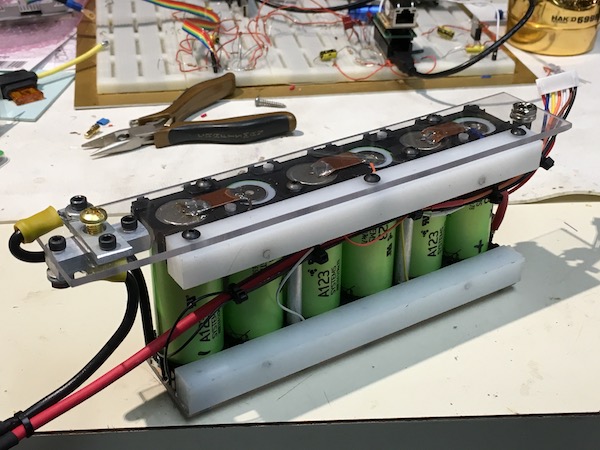

The battery pack. Six A123 cells (26650 size) make 20 volts at no load. The top panel has a charging port on the right end and a homemade power switch on the left. Balancing connections are also on the right.

I used battery holders from AA portable Power as a base for this assembly.

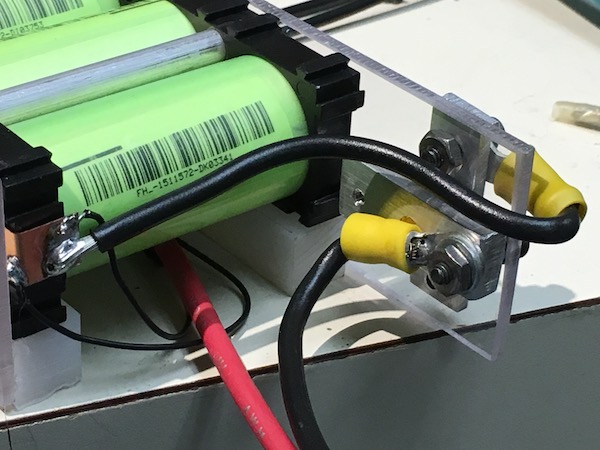

Here's a closeup of the power switch. It's two crossed pieces of aluminum separated by polycarbonate. The lower piece is threaded for a 10-32 brass screw. The upper piece is drilled .275" for plenty of clearance. To complete circuit, tighten screw. Simple.

Power switch bottom view.

The 2.5 inch diameter weapon rotor tube is wrapped with material from a Home Depot floor mat. To help keep it from unwinding I wrapped 3 turns of copper wire around it. Crude but effective. Glue alone is not enough. It's does not adhere to the rubber very well.

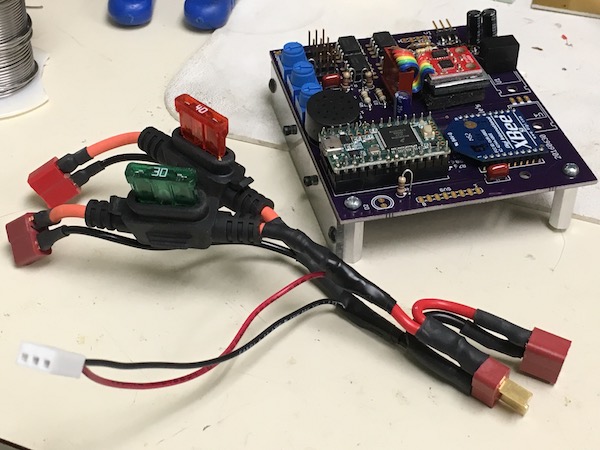

Here is the custom made controller. It can control 4 servo PWM devices and has 2 analog inputs for sensors. The processor is a Teensy 3.2. I used an XBee for the radio and put in a gyro and accelerometer.

Not shown are two Afro 30 amp ESCs for the weapon rotors and two 50 amp Ztw Spider ESCs for the drive motors. They are flashed with SimonK firmware. Each ESC is fused to prevent embarrassing incidents of smoke and fire.

Here he is, pretty much complete except for the polycarbonate covers.

Ready to push and grab because when you're a star you can do anything.

Here's one fight from Robot Battles 63 at MomoCon 2017. Fight starts at 0:30 . We won this one but in general Pushy Grabber has problems with opponents equipped with lifters (There were 3 ). We did not make it to the final. There were some minor programming issues with the onboard controller and I was still learning to drive the thing.

Click for more videos from Robot Battles 63 at MomoCon.

Update Aug. 28, 2017

Pushy Grabber is now equipped with little fingers on the ends of the arms for better grabbing.

I moved the hinge pivot points outside to reduce the space between grabber arms 3 inches to accommodate narrower opponents. I also covered the grabber motors and gearboxes with 0.093 polycarbonate for protection. To keep the bot under 30# with these changes I had to replace the 30 tooth steel drive sprockets with homemade nylon versions identical to the ones in Overthruster.

Next event, Dragon Con Robot Battles Sept. 4, 2017.

Robot Battles 64 at DragonCon 2017

Pushy Grabber got a bye and only had 2 matches. The first was against I can't believe it's not Overhaul by Charles Guan. It's a 30# version of his 250# Battlebots entry and a lifter bot. Pushy Grabber does not do well with lifters. We lost the first round but got lucky and won the next two. Next we were up against Nyx by Mike Jeffries, an excellent lifter bot that has an impressive record of wins. The winner would go to the final against Beaver of Terror. Although MC Kelly said he didn't want me to win I think he secretly wanted to announce "Pushy Grabber vs Beaver of Terror" for the final. Sadly it was not to be. I managed to push Nyx off once but after a bunch of draws Nyx finally prevailed and went on to fight Beaver of Terror. Nyx won the 30# championship.

Pushy Grabber worked well except for one rotary lifter falling off during the match with "I can't believe it's not Overhaul". It took a few minutes in the pits to put it back on and continue. The way I had it attached it was pretty stupid so after we got back from DragonCon I rebuilt the coupler as one piece instead of two. It will not fail again. I also reduced the tubing diameter to 2 inches from 2.5 and wrapped them with rubber from a stronger mat. Photos below.

Also I replaced the soldered copper wire with steel bands to keep the new stronger rubber tread from unraveling. The steel bands were cut from hose clamps and spot welded.

Thanks to the smaller lifter tubes Pushy Grabber now weighs 29 pounds so I have a full 16oz to play with. I have an idea to improve the odds of winning fights with lifters and think it can be done with 16oz. Stay tuned...

May 28, 2018

Pushy Grabber wins Robot Battles 65 at MomoCon. Final at 7:54.

Instead of consistantly losing to Nyx by Mike Jeffries the bot now seems to have a slight advantage due to the new long probe sticking out the front. It gets under high ground clearence bots to lift them on to the rollers. Nyx broke the polycarbonate end just before I pushed him off the stage the final time for the championship.

Now that I know the probe is effective I'll need to do a little re-design to beef it up so it won't break at Dragon*Con Robot Battles 66.

Click here for another video of Pushy Grabber vs Nyx

30# Final, Pushy Grabber vs Nyx

Play list, all 30# fights at Robot Battles 65

Update Aug. 8, 2019

After losing to Styx driven by Ben Hanson at Robot battles 66/MomoCon I realized the rollers can't defeat that kind of wedge, ever. They just can't get a grip on it. Even the long probe I added won't get under the wedge most of the time. Click here for video. Sharpening the point on the probe might get it under the wedge but also cause it to get stuck on stage hazards. So, it's time to re-think the weapon design. Below is the new ultra simple solution which I think will work better against the Styx wedge without sacrificing effectiveness against other bot types.

The new wedges are 4 inch aluminum angle stock shaped with a few simple bandsaw cuts. The top and bottom edges are milled to be flat on the floor surface. They are mounted so they can swing up and down and also swivel so they will always lay flat on the floor. Thanks to symmetry the bot runs inverted just as well.

The dual angled wedges will slip under the front corners of the opponent instead a direct frontal assault. I expect them to glide over various hazards/defects in the DragonCon stage surface as well. These changes lightened the bot by almost 5 pounds. I had to add ballast to bring the weight back up to 30 pounds. It's made of two blocks of steel centered behind the wedges.

Update Sept. 2019

Sadly the new wedges were a big disappointment at Robot Battles 68. The bot "grabbed" just fine but the "push" failed. The Robot Battles stage surface is covered in low pile carpet but my testing was mostly done on concrete. Turns out this makes a big difference. The wedges are hinged so they will always have zero ground clearance. When the opponent is captured between the wedges his weight is only on the wedges, not transferred to my drive wheels. This causes the wedges to dig into the carpet and greatly increase resistance to pushing. So, we have the weight of the wedges plus the opponents weight forcing the wedges into the carpet. Basically there is not enough traction to overcome the friction and Pushy Grabber stalls. Worse yet, the bot is eaiser to push backwards because the wedges slide much easier over the carpet in reverse.

So, as they say, it's back to the old drawing board. I have some ideas to correct those problems but the bot would be non-invertable and need a self righting mechanism. Stay tuned.

Hit Counter = 11996

Previous page: Ooma Telo + Apple Airport Extreme

Next page: Huggy Bear